Fire-stopping is the most commonly installed elements of passive fire protection systems. ASFP’s Niall Rowan explains why correct installation is vital

The concept of fire compartmentation is simple. It aims to keep fire, smoke and noxious gases to a restricted area by dividing a building into fire resisting compartments. So when installing a passive fire protection system, it is important to understand the potential implications of incorrect installation.

When a building is designed there are regulations and codes of practice governing the size of compartments within the building. Each wall, floor and ceiling will have a fire resistance requirement i.e. a period of time for which it must ‘resist’ a fully developed fire. These periods generally range from ½ hour to 4 hours depending on the usage of the premises, the size and location of the compartment and the presence of other protection systems.

The construction of the walls, floors and ceilings will be carried out in accordance with these design criteria. But for any building to be usable, openings will have to be made for doors, windows, mechanical, electrical services and expansion joints, etc. It is these breaches that need to be addressed through the installation of fire-stopping.

There are many proprietary fire-stopping products available that are designed to seal compartment breaches and fill construction joints, thereby reinstating the fire resistance of the wall, floor or ceiling to its original state. These need not only provide a barrier to fire but also need to accommodate the possibility of services burning away and leaving holes in the compartment.

While the primary purpose of fire-stopping is to reinstate breaches in compartment walls and floors, it is also important to remember that they serve other functions as well. If you want to block an opening to stop a flame going through, the easiest way would be to bolt a steel plate over the hole. However, although this would stop the flame, the heat transmission through the steel would lead to materials combusting on the non-fire side of the wall or floor, and the fire would spread into the next compartment. Consequently, the fire resistance of separating elements is expressed in minutes of Integrity (preventing the passage of flames and hot gases) and Insulation (limiting the temperature rise on the unexposed face). If a product has a claimed fire resistance of 60 minutes, the end-user should be satisfied that it satisfies both Integrity and Insulation for this period.

It is important to ensure that the product specified is suitable for the intended application. Check the product’s fire test and other evidence to ensure it adequately supports the end use application for which it is being used. Similarly, never mix products from one manufacturer with those of another manufacturer. If such products have not been tested together, they may not work. See ASFP Advisory Note No.6: Mixing and matching components.

Installation best practice

In many applications, fire-stopping products have to accommodate movement of the services or joints in everyday usage. Sealants used around hot water pipes, or chiller pipes, can be subject to expansion, or contraction of the pipework that will produce both tensile and shear loads on the product. If the product is incapable of meeting this criteria it is likely that it will fail when exposed to fire.

Similarly, the gap between the slab edge and a curtain wall construction will be subject to movement of the curtain wall façade due to positive and negative wind loads. Any fire-stopping product used in this application should be able to demonstrate its ability to recover its shape through testing. Facade movement must be accommodated by a flexible seal that must be adhered or mechanically fixed to the slab according to the manufacturer’s guidelines. See ASFP Advisory Note No. 7: Horizontal linear joint seals.

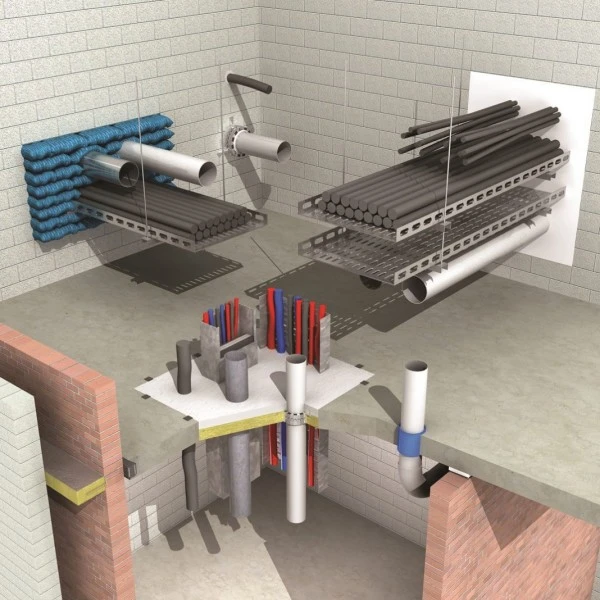

Mixed penetrations

There is a tendency for building designers and others to put all the M & E and other services together in one opening, either out of convenience or due to a lack of consideration in the design. However, the type of penetration seals used for each service differs and the reality is that such a ‘mixed penetration’ seal will fail prematurely. Consequently, the ASFP recommends that fire resisting compartment walls/floor which are to be penetrated by services should be designed at an early stage in the project so that the correct type of seal can be used with each penetrating service apertures.

In most cases, this should result in segregation of the penetrating services into different openings so that the correct type of seal and support can be provided. If a mixed penetration seal has already been constructed which requires fire-stopping, guidance will need to be obtained from the manufacturer of the seals to ensure that they can be used for all penetrating services.

Ensuring competency

The ASFP recommends that fire-stopping work should only be carried out by third party certified contractors. When appointing a contractor, it is important to ensure that they can prove competency for installing the type of fire protection product to be used. All ASFP contractor members are third party certificated, so always look for the ASFP logo.

The ASFP also recommends that a complete record is made of all installations within a building, with labels applied as part of the certification process. This assists with traceability for future remedial work. Similarly, photographs of the completed installation can also assist with verification of the work. A certificate of completion must also be provided as part of the inspection process.

Available guidance

To assist specifiers, building owners and installers in installing the most appropriate product in the correct way, the ASFP offers a range of guidance documents.

The Association’s video on the correct specification and installation of fire-stopping describes the vital role of compartmentation in limiting the spread of fire and smoke within buildings and explains why any breaches in compartment walls and floors for service openings must be appropriately sealed, or ‘fire-stopped’, to ensure their continued performance.

It highlights the inappropriate use of PU foams and explains that such foams are sometimes sold on the basis of their performance in less severe reaction to fire tests; or, where they have passed more severe fire resistance tests, are often used far outside the scope of their tested performance.

Featuring footage of a fire test carried out on behalf of the ASFP, the video clearly demonstrates how correctly installed fire-stopping can effectively hold back smoke and fire; while incorrectly chosen and installed fire-stopping will fail, allowing smoke and flames to spread quickly.

Its On-Site Guide to Installing Fire Stopping offers general advice on site conditions and typical pre-installation checks, as well as offering detailed advice on best practice for the installation of products in particular types of application.

With the aid of detailed colour illustrations, it highlights applications and details factors that should be considered for walls and ceilings; pipes; cables; fire doors; air conditioning and ventilation systems; as well as service supports.

Other available guidance includes the ASFP ‘Red Book’, Fire stopping: Linear joint seals, penetration seals & small cavity barriers, as well as. Technical Guidance Note (TGD) 17: Code of practice for the installation and inspection of fire-stopping and a range of Advisory Notes which offer advice on particular aspects of fire-stopping.

For further information on passive fire protection, or to download free copies of ASFP guidance documents, visit www.asfp.org.uk