Product Description

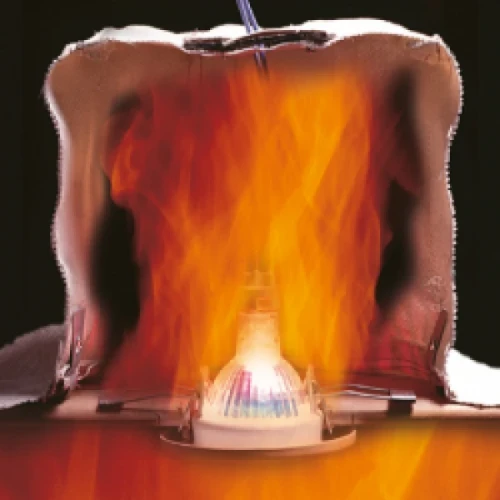

Envirograf INTUMESCENT DOWNLIGHTER COVERS AND CAGES

The ever growing use of down lighters within the industry, the integrity of the plasterboard and suspended ceilings can be reduced to approximately 4 minutes. Passive Fire Products Envirograf® downlighter covers are used to restore the integrity required by British Standards.

The covers available in many standard sizes, or made to order. They are easily installed in about five minutes from below or above the ceiling, with cable entries on top, the intumescent covers are ventilated to avoid light fittings overheating. Cables can also be passed under the the rim of the cover for connections to transformers. Only the light fitting penetration is required to be protected, not the transformer.

ADVANTAGES

– Maintains the fire rating of plasterboard or suspended ceilings rated up to 4 hours

– Available in standard and acoustic forms, preventing sound transfer from different floors of a building up to 63dB

– Can be made to accommodate downlighters alone, or downlighter/transformer combos

– Downlighter cages are a sturdier option, allowing for insulation to be laid over the top after they are fixed in place – ideal for lofts

– Can be used to improve the fire rating of ceiling-mounted speakers as well as downlighter

– The range also contains downlighter adaptors which can convert existing light fittings to fire resistant, low-energy units, saving up to 40W per light whilst providing 66 minutes of fire protection

– Easily installed in 5 minutes or less. Custom sizes made to order.

APPLICATION INSTRUCTIONS

Lead the cable from the transformer through the pre-cut downlight aperture in the ceiling

Pierce the cable entry point in the top of the cover with a sharp object, creating an opening large enough to suit the cable size

Feed sufficient cable through the opening for the connection

Compress the cover and pass it through the aperture in the ceiling

Open out the cover once inside the ceiling, away from the light fitting

Using the two supplied pins, fasten opposite inner flanges of the cover to the plasterboard

Insert the light fitting and fasten the closing mechanism over the inner flaps of the downlighter cover to seal the opening

Downlighter covers require a minimum of 40mm horizontal clearance and 15mm vertical clearance

Cages are rigid and require no clearance, meaning that insulation can be packed around them as long as it does not cover the ventilation holes

NB: Downlighter cages cannot be compressed to fit through the light fitting aperture from below and must therefore be positioned from above

Product Performance

This product has been tested employing the general procedures of BS476 Parts 22, 23, and 23 (Clause 5) (1987), in various ceiling and floor constructions. Integrity results of up to 240 minutes have been achieved. Also tested to NEN 6069 (1997).

Data Files and Downloads

Related Products

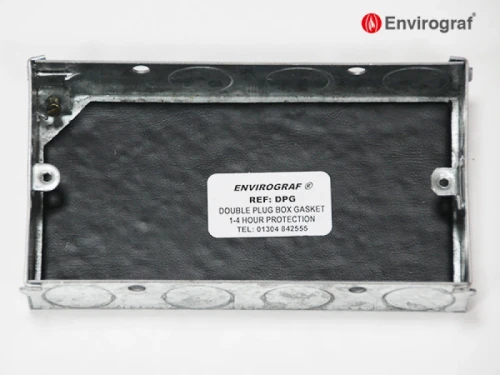

Material Specification:Multigraf Intumescent material chemical constitutionMineral Wool Fibre 20-70%...

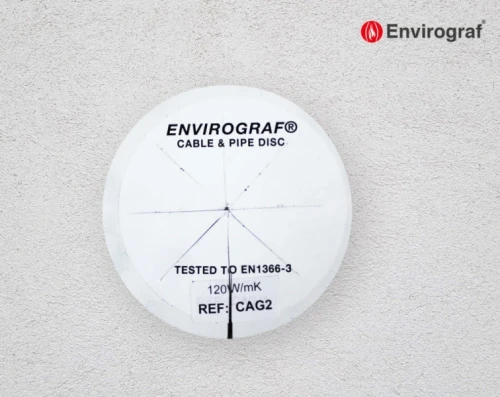

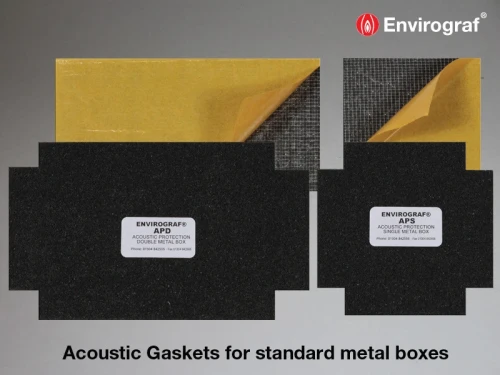

Lightweight and flexible, fire protection gaskets for metal boxes can accommodate wires and cables b...

BESA or universal boxes must have intumescent gaskets fitted to stop fire penetrating. Furthermore, ...

Fully ventilated to prevent units from overheating, providing effective fire as well as acoustic pro...

According to fire statistics, overheated light fittings and electrical faults are a leading cause o...

Envirograf intumescent fire prevention ventilation grille consisting of an inner and outer plate hav...

Tested on a wide range of wooden doors, achieving 60 minutes integrity and either 30 or 60-minute fi...

A water-based wood filler which is fireproof when cured. It is used to: (a) fill gaps in cracked or ...

Fire protection for ducting and ventilation systems that pass through the fire-rated block, brick, c...